1. 1. Cov qauv ntawm cov xaim hluav taws xob

Cov xov hlau yog cov nqa khoom xa hluav taws xob thiab cov khoom siv tam sim no. Lawv feem ntau yog tsim los ntawm rwb thaiv tsev thiab xaim. Hlau ntawm txawv specifications sib txawv cov ntaub ntawv rwb thaiv tsev thiab tooj liab hlau qauv. Cov kev ntsuas ntsuas ntawm cov xaim feem ntau suav nrog cov tooj liab hlau txoj kab uas hla, tus naj npawb, rwb thaiv tsev thickness thiab sab nraud txoj kab uas hla ntawm tus neeg xyuas pib. Txhawm rau txo qhov kev cuam tshuam ntawm cov teeb liab sib txawv thaum lub sij hawm kis tau tus mob, twisted-pair xov hlau thiab shielded xov hlau kuj siv nyob rau hauv tsheb. Vim muaj ntau cov xov hlau siv nyob rau hauv lub tsheb, rau qhov yooj yim ntawm txoj hlua khi ntau lawm thiab kev muag khoom tom qab kev muag khoom ntawm tag nrho lub tsheb, cov xim sib txawv feem ntau yog teem rau lub rwb thaiv tsev ntawm daim tawv nqaij kom paub qhov txawv ntawm lawv.

1. 2. Specifications ntawm cov xov hlau

Cov xov hlau siv hauv tsheb yog cov xaim hluav taws xob tsawg. Nrog rau txoj kev loj hlob ntawm hybrid hluav taws xob tsheb thiab tsheb hluav taws xob ntshiab, ntau thiab ntau lub zog hluav taws xob xaim hlua siv hauv tsheb. Txawm li cas los xij, tus sau ntawm tsab xov xwm no feem ntau tham txog cov xov hlau uas tsis tshua muaj hluav taws xob, nrog rau kev lag luam tam sim no cov ntsiab lus ntawm cov xov hlau yog Japanese tus qauv xov hlau thiab German tus qauv xov hlau.

2. Tsim thiab xaiv cov khoom siv hauv tsheb

2. 1. Hlau ampacity

Lub ampacity ntawm cov xov hlau yog ib qho tseem ceeb uas yuav tsum tau xav txog nyob rau hauv tus txheej txheem tsim, thiab load tam sim no tus nqi ntawm cov xov hlau yog teev nyob rau hauv GB 4706. 1-2005. Lub peev xwm nqa tam sim no ntawm cov xaim muaj feem cuam tshuam rau ntu ntu ntawm cov xaim, thiab tseem cuam tshuam nrog cov khoom siv, hom, qhwv txoj kev thiab qhov ntsuas kub ntawm cov hlau. Muaj ntau yam cuam tshuam thiab kev suav yuav nyuaj dua. Lub ampacity ntawm ntau cov xov hlau feem ntau tuaj yeem pom hauv phau ntawv.

Cov yam ntxwv cuam tshuam rau ampacity tuaj yeem muab faib ua cov yam ntxwv sab hauv thiab lwm yam. Cov khoom ntawm cov hlau nws tus kheej yog cov khoom siv sab hauv uas cuam tshuam rau lub peev xwm nqa tam sim no ntawm cov hlau. Ua kom lub hauv paus tseem ceeb, siv cov khoom siv hluav taws xob siab, siv cov ntaub ntawv insulating uas muaj qhov kub thiab txias tsis kam thiab thermal conductivity, thiab txo kev tiv thaiv kev tiv thaiv tuaj yeem ua rau muaj peev xwm nqa tau tam sim no ntawm cov hlau. Cov yam ntxwv sab nrauv tuaj yeem ua rau kom muaj zog ntxiv los ntawm kev ua kom cov hlau layout qhov sib txawv thiab xaiv qhov chaw teeb tsa nrog qhov ntsuas kub kom haum.

2. 2. Kev sib txuam ntawm cov xov hlau, cov khoom txuas thiab cov khoom siv

Qhov sib txuam ntawm cov xov hlau thiab cov khoom txuas txuas yog feem ntau muab faib ua qhov sib txuam ntawm cov khoom nqa tam sim no thiab kev sib txuam ntawm cov tshuab crimping qauv.

2. 2. 1. Kev sib txuam ntawm cov khoom nqa tam sim no ntawm cov terminals thiab cov xov hlau

Lub peev xwm nqa tam sim no ntawm cov terminals thiab cov xov hlau yuav tsum sib phim kom ntseeg tau tias ob lub terminals thiab cov xov hlau tuaj yeem ua tau raws li qhov yuav tsum tau ua thaum siv. Qee zaum, qhov tso cai tam sim no tus nqi ntawm lub davhlau ya nyob twg yog txaus siab, tab sis qhov tso cai tam sim no tus nqi ntawm cov xaim yog dhau, yog li yuav tsum tau them nyiaj tshwj xeeb. Lub peev xwm nqa tam sim no ntawm cov xov hlau thiab cov terminals tuaj yeem tau los ntawm kev saib cov rooj thiab cov ntaub ntawv ntsig txog.

Tus nqi tam sim no tso cai ntawm cov hlau: cov khoom siv hauv lub davhlau ya nyob twg yog tooj dag, tus nqi tam sim no thaum lub davhlau ya nyob twg kub yog 120 ℃ (qhov kub-tiv taus ntawm lub davhlau ya nyob twg) thaum muaj zog; lub tshav kub-resistant tooj liab alloy, tus nqi tam sim no thaum lub davhlau ya nyob twg kub yog 140 ℃ (lub tshav kub-resistant kub ntawm lub davhlau ya nyob twg) tus nqi.

2. 2. 2. Kev sib txuam ntawm lub davhlau ya nyob twg thiab xaim ampacity mechanical crimping ib feem

Txhawm rau kom ntseeg tau qhov sib txuam ntawm cov tshuab crimping qauv, uas yog, cov terminals yuav tsum ua tau raws li qee cov qauv tom qab crimping cov xov hlau. Cov kev cuam tshuam feem ntau suav nrog cov hauv qab no:

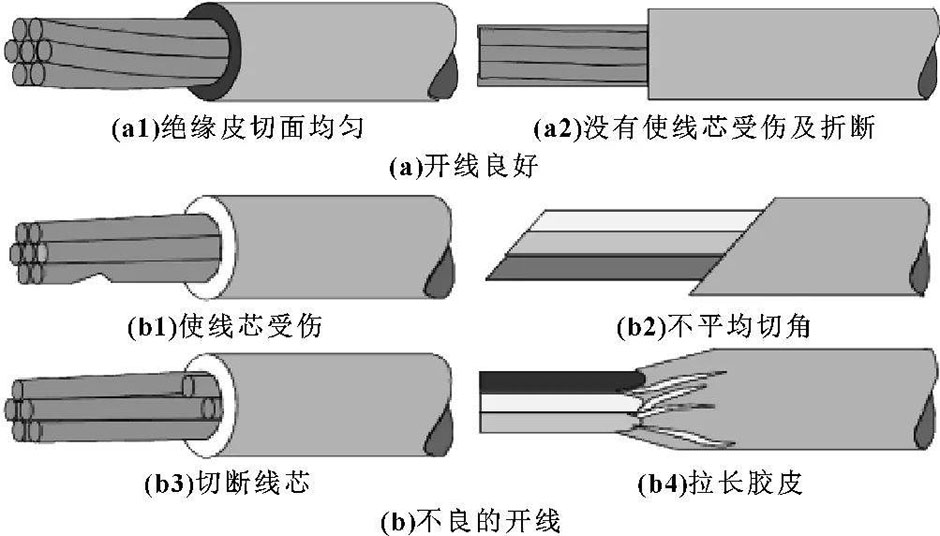

(1) Thaum cov xov hlau raug qhib, nws yuav tsum xyuas kom meej tias cov rwb thaiv tsev thiab cov tub ntxhais ntawm cov hlua hlau tsis zoo thiab tsis muaj kev puas tsuaj. Tus qauv raug tom qab qhib yog qhia hauv daim duab.

Post lub sij hawm: Dec-23-2022